Kenya’s sugar industry is sitting on a vast, untapped clean energy resource, but punitive electricity tariffs, outdated mills, and high costs of connecting to the national grid are preventing millers from fully exploiting cogeneration.

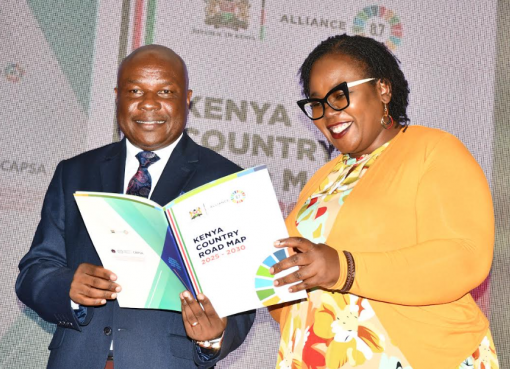

Kenya Sugar Board chairman Eng. Nicholas Gumbo said the country’s 20 licensed sugar factories could collectively generate up to 300 megawatts of electricity from bagasse if the legal, financial, and infrastructural hurdles currently holding back the sector were removed.

“A typical mill with a crushing capacity of 3,000 tonnes of cane per day can produce about 15 megawatts of electricity, yet most factories today use only a fraction of that internally, leaving the bulk of potential energy untapped,” he said.

The chairman emphasised that the biggest impediment is the unfavourable power purchase agreements (PPAs) currently offered by Kenya Power, which do not reflect the cost of production or the investment required to modernise factories.

“If I generate power at three cents and you offer me two cents, I cannot sell. You cannot invest billions in boilers and modern technology only to sell power at a loss,” he said.

Gumbo also highlighted the prohibitive distances of some factories from the grid, noting that many mills are 20 to 40 kilometres away from the nearest transmission line, forcing them to incur expensive connection costs.

He added that even after Parliament lifted the moratorium on new PPAs, millers continue to complain that tariffs remain punitive, making it economically unfeasible to transport surplus energy from factories to the national grid.

Speaking during the Sugar Symposium and Expo 2025 in Kisumu, Gumbo said cogeneration should be treated as a core part of the modern sugar industry rather than an ancillary activity.

He called for a shift in perspective from viewing sugarcane merely as a source of sucrose, noting that soluble sugars account for only 15 percent of the plant, while fibre, water, and other by-products make up the rest.

These by-products, he said, could be harnessed for electricity generation, ethanol production, and other industrial uses.

He urged that distilleries and cogeneration plants be sited adjacent to sugar mills to maximise efficiency and create a fully integrated value chain.

Gumbo also noted that the government’s fuel blending policy has yet to be fully operationalised, limiting the market for ethanol derived from molasses, while bagasse-generated electricity could contribute significantly to stabilising the national grid and reducing load-shedding.

Gumbo further explained that plant modernisation was essential for unlocking the sector’s cogeneration potential.

“Many factories still rely on outdated equipment that wastes steam and reduces power output. New machinery can convert high-pressure steam from bagasse into electricity efficiently, but the current combination of legal hurdles, unfavourable tariffs, and costly grid access has discouraged millers from investing,” he said.

Despite the challenges, Gumbo expressed optimism, noting that the Sugar Board was engaging the Ministries of Energy and Treasury to review PPAs so that millers can sell electricity at rates that cover production and transmission costs.

Describing sugarcane as a carbon-neutral crop, Gumbo said cogeneration offers both economic and environmental benefits.

“Sugarcane absorbs carbon as it grows and releases it during processing. It is a perfect carbon cycle. Capturing this energy could unlock new revenue streams, boost miller profitability, and contribute to a climate-resilient and sustainable industry,” he said.

He urged industry stakeholders to embrace modernisation and innovation to exploit the sector`s full potential.

“These challenges are not insurmountable. The potential is enormous, and with boldness, collaboration, and investment in modern technology, Kenya can harness this energy to benefit farmers, millers, and the country as a whole,” he said.

The three-day expo brings together millers, farmers, researchers, financiers, policymakers and young innovators as Kenya pushes to reposition the sugar industry as a modern, diversified, climate-resilient and profitable sector.

Gumbo told the symposium, which features young innovators showcasing new technologies, that the future of the industry depends on translating ideas into incubated, functional solutions.

“The role of innovation is to move from ideas to incubation. Let the ideas take physical form and generate income for innovators and for the country,” he said.

With the reforms and investments envisioned, Gumbo projected that farmers could earn at least Sh15,000 per tonne of cane within the next ten years—up from the current average of about Sh6,000.

“I am very optimistic,” he said. “This will require boldness, belief in ourselves and industry-wide collaboration. But it is within our grasp,”.

By Chris Mahandara